Introduction

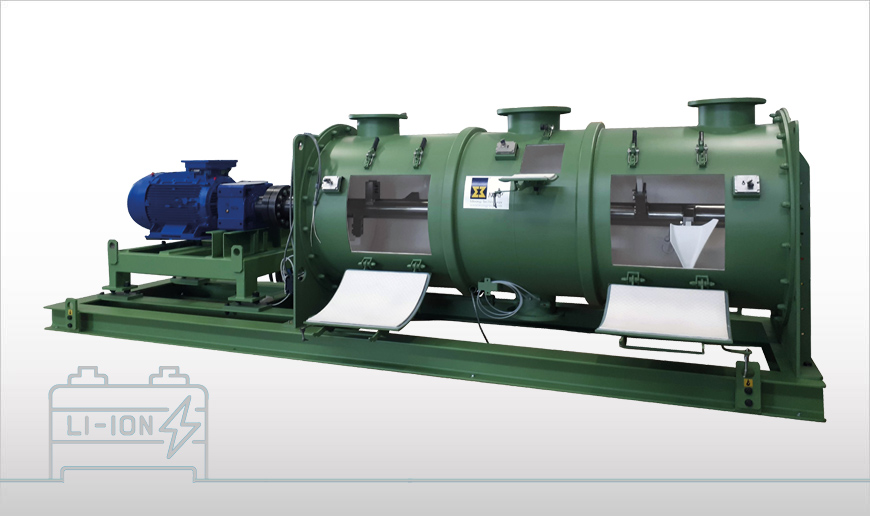

The WBH Lithium High-Efficiency Ploughshare Mixer is the ideal machine for obtaining highest quality mixtures in perfectly reproducible batches. Over the last four decades MAP® has supplied thousands of mixers to a large variety of industries. Mixing tests for customers are performed in the Group’s own laboratories worldwide

Simple: streamlined user-friendly processes

Reliable: no product temperature increases during the mixing process

Technical Specs

Description

As a result of decades of experience in the field of mixing technology, MAP® has developed specialised solutions for the Secondary Battery Industry. WBH Lithium is the ideal mixer for those looking for a high-quality machine without the risk of product contamination. WBH Lithium is easy to clean and maintain, features short mixing time and low energy consumption. The mixer is durable and has a wide range of specialised abrasion and corrosion-resistant coatings and linings. WBH Lithium is an investment that will pay off in years, making it an excellent choice for industrial-scale operations.

Function

The WBH Lithium Horizontal Single-Shaft Batch Mixer is based on the principle of mechanical fluidisation of the product. The special shape, position, and rotational speed of the mixing tools create a centrifugal vortex motion, which allows the materials to be projected three-dimensionally and to merge together. This ensures that ingredients with different particle sizes and bulk densities are mixed perfectly and with high precision within the shortest possible time.

Features

- Capacity: 75 ~ 25,000 litres (2.6 ~ 880 cu ft) per batch

- Mixing ratio: 1/100,000

- Optional liquid addition

- Manufactured from 304L / 316L stainless steel

- Pneumatic control panel

- End bearing assemblies with special patented shaft seals for battery powder

- Adjustable, replaceable mixing tools

- Different inlet options

- Heavy-duty mixing chamber manufactured from 304L / 316L stainless steel

- Inspection door enabling comfortable access to the interior of the mixer

- Flush discharge valve

- Choppers (Tulip-type and Blade-type)

- Wear and corrosion-resistant ceramic-tile chamber lining

- Special outlet with cleaning system

- Specially coated ploughshare tools

Benefits

- Simple: streamlined, user-friendly processes

- Fast: short mixing time

- Reliable: no product temperature increases during mixing process

- Reduced energy consumption: low power installed (e.g., 75 kW on 3,000-litre mixer)

- Durable: minimised wear of tools and mixing chamber

- Safe: easy cleaning and maintenance